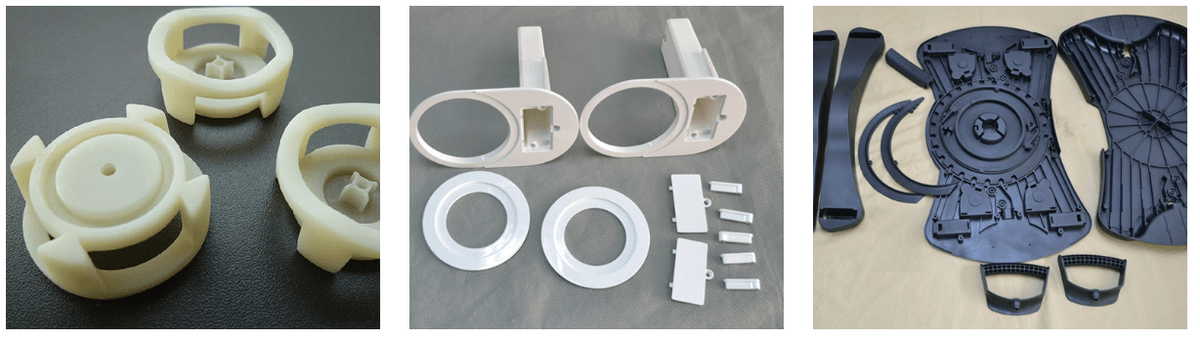

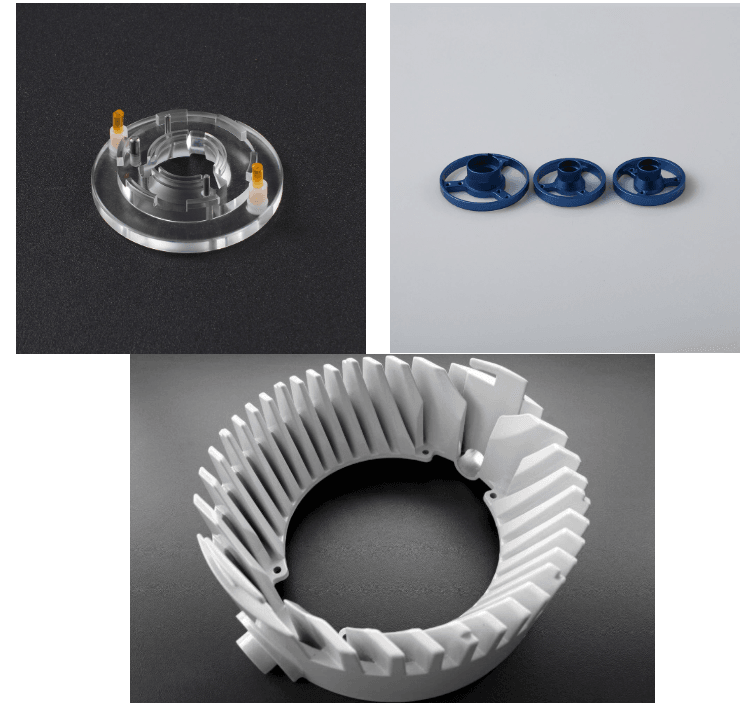

We produce CNC plastic parts based on the 3D data provided by our clients. Our process includes:

- Program development from the 3D model and output to CNC machining centers for precision cutting

- Removing excess material according to the design

- Hand finishing tasks such as deburring, assembly, and quality verification to ensure full compliance with client specifications

We also offer post-processing services to meet your product requirements, including:

- Painting, silk-screening, pad printing, laser engraving, electroplating, hydrographic printing, decals, UV coating, coloring, etching, and mirror hot stamping

Our manufacturing capabilities are supported by a wide range of equipment:

- Automatic lathes, CNC lathes, CNC machining centers

- Auxiliary equipment such as milling machines, drilling machines, and painting facilities

- A total of over 300 machines to ensure efficiency and precision

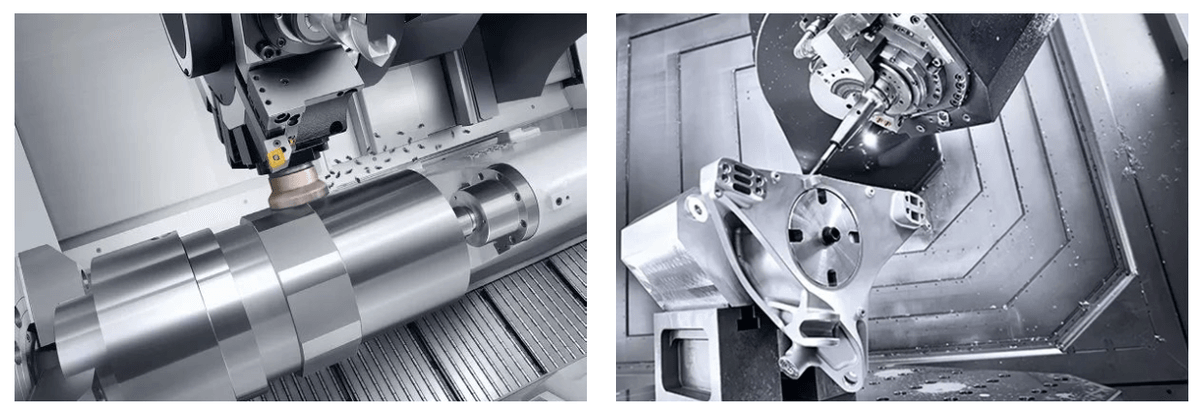

CNC Milling

Milling is a type of material removal process used to produce precise parts by cutting away unwanted material. The process involves:

- Using milling machines or lathes, along with the workpiece, fixtures, and cutting tools

- Securing the workpiece (pre-shaped material) in a fixture, which is mounted on the machine

- High-speed rotation of the cutting tool or workpiece to remove material in small chips, shaping the workpiece according to design specifications

- Some operations may use multi-axis tools for complex geometries

CNC milling allows for high precision and consistency in producing components with complex shapes.

Precision CNC Machining

Precision CNC machining is a manufacturing process that uses computer-controlled machine tools to produce high-accuracy parts. The tools commonly used include lathes, milling machines, cutters, and grinders.

- Machine tool accuracy typically ranges from 0.001 to 0.002 mm

- Considering tool tolerances and secondary clamping, the final part tolerance usually falls between 0.02 and 0.1 mm

This process ensures consistent precision and high-quality production for complex components.

CNC Machining Design Tips

Every rapid prototyping service has its own design guidelines. Following these rules can help you create highly successful prototypes. For precision CNC machining, several simple design practices can improve your prototype without negatively affecting the part’s appearance or functionality.

Example: Hole Depth

- Keep the hole depth-to-diameter ratio at 10:1 or less for easier CNC machining.

- Deeper holes may require specialized deep-hole drilling techniques.

For more rapid prototyping design tips, including:

- Prototype injection molding design tips

- Vacuum casting (polyurethane) design tips

- 3D printing prototype design tips (SLA & SLS)

please visit our Services page.

Our Core Focus

We provide rapid prototyping starting from just 1 piece and small-batch manufacturing up to 100,000 parts.

We don’t limit you to pre-defined manufacturing solutions. Instead, we work with you to create custom solutions tailored to your project requirements.